Ferlin One premiere at the K-Exhibition

We've been talking about our newest dispensing machine in development, the Ferlin One, for months. But... now it's finally almost here; it's only 56 days until the official world premiere at the K-Fair in Düsseldorf, Germany! Back to the beginning At Ferlin, the customer always comes first. The idea of the [...]

Save on production costs with Ferlin

Find out how to regain control of your production costs with Ferlin.

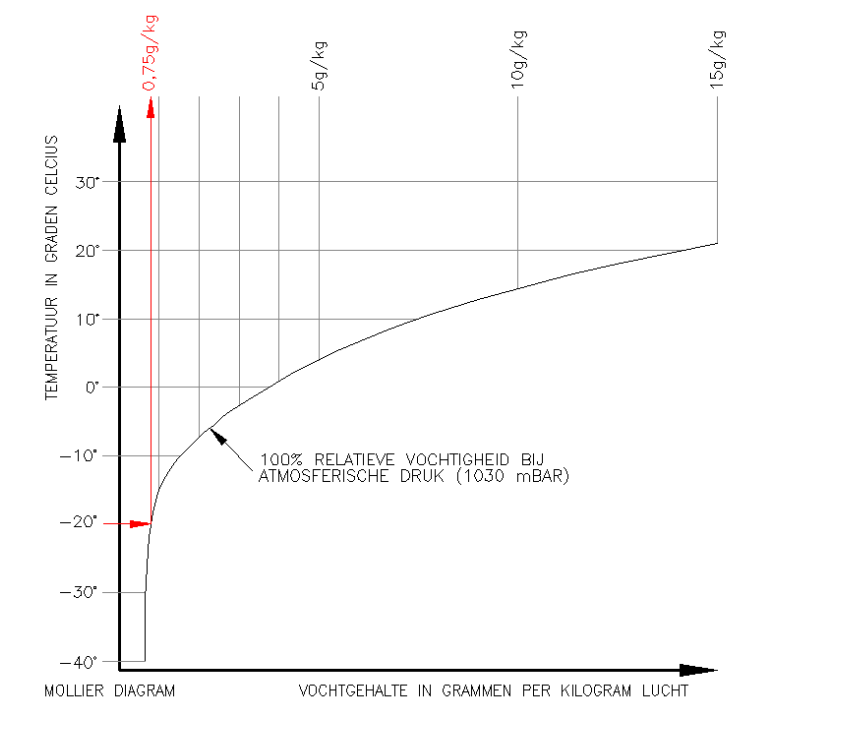

Is a dew point Of -40°C twice as good as -20°C?

What is Hygroscopic material? Most plastic materials, such as PA (Nylon), PC and PET are hygroscopic. They absorb moisture from the ambient air and release moisture to the dry air. To release moisture back to the ambient air, the airflow around the pellet must have a dew point of at least -15°C. Process air with a dew point lower than [...]

New premises

At Ferlin, we are constantly innovating and growing. After spending many years in our current building, we are ready for a new location where we have more space to continue innovating and growing. Our new building will be realized by Hoek Bouwprojecten BV and will be as sustainable and climate-friendly as possible.

3 ways Ferlin continues to innovate in 2022

At Ferlin we keep innovating, so we can always guarantee the most customer-friendly products and services. That's why we take a critical look at our own processes and working methods and stay abreast of the latest technologies, trends and developments. In this article, we explain how we always develop the most innovative solutions [...].

5 reasons to stop using compounds

A compound is a composed material that is made on the basis of customer-specific requirements. It usually contains additives such as UV stabilisers or release agents, and the compound is made in the right colour. The advantage for a plastic processing company is that they no longer have to worry about the dosage of the compound.

Research: Save thousands of euros!

Discover how you can save thousands of euros every year per dosing machine! This month the results were published of a comparative study on gravimetric depositors for the plastics industry. The study examined the differences between dosing machines that measure weight loss (LIW) and Ferlin's dosing machine that measures weight gain (GIW). Read on now to find out which [...]

5 major advantages of self-dosing

ECONOMICAL ADVANTAGES A compound is always more expensive than dosing natural, masterbatch and additives yourself. After all, the company that supplies the compound must dose it itself and then extrude it. Then there is transport. In addition, there is often a request to keep several colours in stock. In order to [...]

Different ways of dosing

The dosing of materials can provide enormous cost savings for plastics processing companies. Additives and masterbatch are often some of the most expensive sources companies use. The way materials are dosed shows its effect on cost reduction. Manual dosing One of the oldest methods for dosing materials is manual dosing. Often a [...]

Saving on masterbatch and additives

For many plastics processing companies, the resources to make their product often amount to around 20% or even more of the company's total costs. Saving on resources can be a crucial part of gaining a strong competitive advantage. In this article, we explain how you can save on masterbatch and additive [...].